Lintlha tsa Sehlahisoa

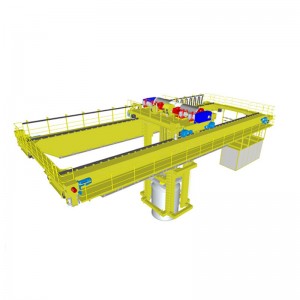

Forging Casting Workshop Overhead Crane

-

Boima ba moroalo

180t~550t

-

Nako ea crane

24m ~ 33m

-

Bophahamo ba ho phahamisa

17m ~ 28m

-

Mosebetsi oa ho sebetsa

A6~A7

Kakaretso

Kakaretso

Ho forging ke mokhoa oa ho etsa tšepe ka ho sebelisa mocheso le khatello.Crane ea forging overhead ke sesebelisoa sa bohlokoa ts'ebetsong efe kapa efe ea ho qhekella.E etselitsoe ho phahamisa le ho tsamaisa meroalo e boima ea tšepe ho tloha sebakeng se seng ho ea ho se seng habonolo.Crane hangata e entsoe ka tšepe e matla a holimo 'me e khona ho phahamisa litšepe tse pakeng tsa lithane tse 5 le 500, ho latela boholo le bokhoni ba crane.

Ho phaella moo, crane ea forging e khona ho sebetsa sebakeng se phahameng, e leng se etsang hore e be se loketseng bakeng sa ho tsamaisa likotoana tse kholo tsa tšepe ho tloha mokatong o mong oa setsi sa ho haha ho ea ho o mong.E boetse e etselitsoe ho sebetsa maemong a feteletseng, ho kenyelletsa mocheso o phahameng le maemo a thata, e leng se etsang hore e be sesebelisoa se ka tšeptjoang le se tšoarellang bakeng sa ts'ebetso efe kapa efe ea forging.

Tšebeliso ea crane ea forging overhead e fetotse mokhoa oa ho qhekella, ho etsa hore e sebetse hantle le ho bolokeha ho basebetsi.Ka crane, basebetsi ha ba sa tlameha ho phahamisa meroalo e boima ka letsoho, e ka lebisang khatellong le kotsi.Ho e-na le hoo, crane e ba phahamisetsa boima bo boima, e lumellang basebetsi ho tsepamisa maikutlo mesebetsing e meng ea bohlokoa.

Ho feta moo, ts'ebeliso ea crane ea forging e ekelitse tlhahiso litsing tsa ho qhekella.Ka crane, basebetsi ba ka tsamaisa meroalo e boima ka potlako le ka nepo, e ba lumellang ho qeta mesebetsi e mengata ka nako e nyane.Sena, ka lehlakoreng le leng, se eketsa tlhahiso ea kakaretso ea setsi, se hlahisang phaello e eketsehileng le kholo.

Ha re phethela, crane ea forging overhead ke sesebelisoa sa bohlokoa indastering ea ho qhekella.Theknoloji ea eona e tsoetseng pele, ho tšoarella le ho sebetsa hantle ho e etsa sesebelisoa sa bohlokoa bakeng sa ts'ebetso efe kapa efe ea ho qhekella.

Sebaka sa pokello ea lintho

Melemo

Morero Khothalletsa

Lihlahisoa tse Amanang

Ikopanye

Haeba u na le lipotso, u amohelehile ho letsetsa le ho siea molaetsa Re emetse ho ikopanya le hau lihora tse 24.

Botsa Joale